The Taskmaster High Velocity Oxygen Fuel thermal spray process provides High Density coatings with almost Negligible Porosity levels

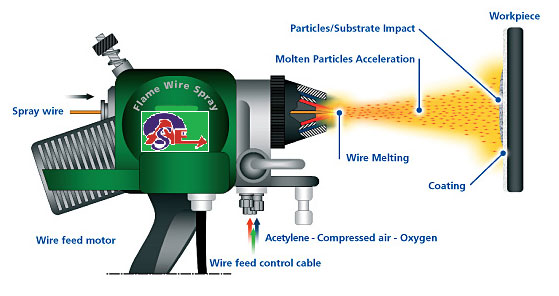

Quantity : 1 Schematic view of Flame Spray process gun

Price : 1

Thermal Spray Process

|

Flame spraying is a thermal spraying process that uses an oxy-fuel gas flame as a source of heat for melting the coating material. Compressed air is usually used for atomizing and propelling the material to the work piece. There are two variations: one uses metal in wire form and the other uses materials in powder form. The method of flame spraying which uses powder is sometimes known as powder flame spraying. The method of flame spraying using wire is known as metalizing or wire flame spraying.

In both versions, the material is fed through a gun and nozzle and melted in the oxygen fuel gas flame. Atomizing, if required, is done by an air jet which propels the atomized particles to the work piece. When wire is used for surfacing material, it is fed into the nozzle by an air-driven wire feeder and is melted in the gas flame. When powdered materials are used, they may be fed by gravity from a hopper which is a part of the gun. In another system, the powders are picked up by the oxygen fuel gas mixture, carried through the gun where they are melted, and propelled to the surface of the work piece by the flame.

Figure shows the flame spray process using wire. The version that uses wires can spray metals that can be prepared in a wire form. The variation that uses powder has the ability to feed various materials. These include normal metal alloys, oxidation-resistant metals and alloys, and ceramics. It provides sprayed surfaces of many different characteristics.

The Basics : All thermal spraying processes rely on the same principle of heating a feed stock, (Powder or Wire) and accelerating it to a high velocity and then allowing the particles to strike the substrate. The particles will then deform and freeze onto the substrate. The coating is formed when millions of particles are deposited on top of each other. These particles are bonded by the subst[..]

Our company PROCURED WORLD LATEST HVOF SYSTEM FROM TAFA - PRAXAIR Excellence Flame Velocity & Particle Velocity. FLAME TEMPERATURE DURING COATING around 3,000 °C and high bond strength 10,000 psi – HVOF is the latest thermal spray system which is getting wide acceptance worldwide because it finds diverse applications in a cross section of industries. Coatings applied by our HP/HVOF [..]

Flame spraying is a thermal spraying process that uses an oxy-fuel gas flame as a source of heat for melting the coating material. Compressed air is usually used for atomizing and propelling the material to the work piece. There are two variations: one uses metal in wire form and the other uses materials in powder form. The method of flame spraying which uses powder is sometimes known as powder fl[..]

Electric arc spraying is a thermal spraying process that uses an electric arc between two consumable electrodes of the surfacing materials as the heat source. A compressed gas atomizes and propels the molten material to the workpiece. The principle of this process is shown by figure. The two consumable electrode wires are fed by a wire feeder to bring them together at an angle of approximatel[..]